Search

Besides BÖHLER tool steels and high speed steels, Bohlasia also provides

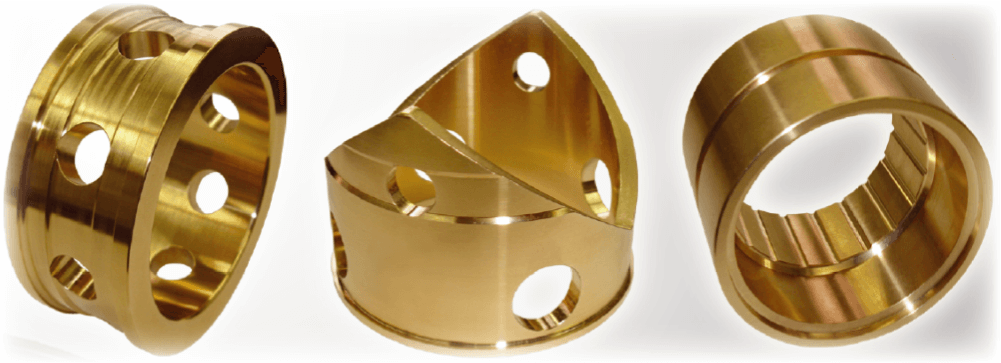

Bohlasia Steels started its cooperation with AMPCO Metal S.A. in 2008. This partnership is a natural extension of our philosophy and mission as a metallurgical solution provider in the Malaysian market.

AMPCO METAL, with its headquarter located in Marly, Switzerland, is a leading international manufacturer and integrated distributor of specialty copper alloys and engineered products.

The company was founded in 1914 in USA as an innovator in the introduction and application of aluminium bronze alloys. It has also introduced to the market several new metallurgical and process techniques that have made AMPCO METAL the recognized quality leader in specialty bronzes and copper alloys. The major industries served include: chemical and petroleum, machine tool, primary metal producers, transportation and a wide range of industrial and commercial machinery.

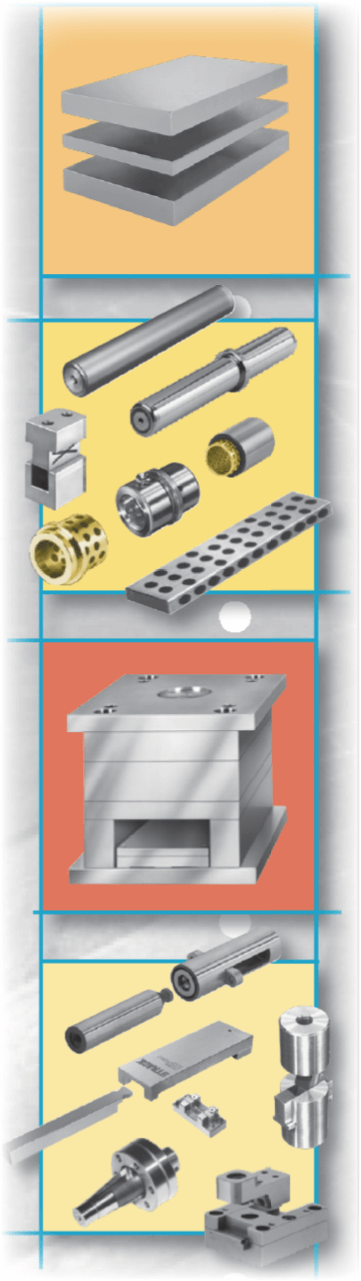

The STRACK Group originated from the works agencies set up by the company founder Friedrich Strack. In 1936, it started the independent production of high-quality cylinder pins and in 1948 production of standard parts for punching and forming applications, dies and metal-cutting band saws. By 1959, the range expanded to include the supply of standard parts for injection and die-casting moulds, standard parts for elastomer applications and for the construction of jigs and fixtures.

Today, STRACK NORMA catalogue of dies, moulds and individual parts has become a basic requirement for designers and mould makers, offering over 150,000 individual parts and complete dies and moulds.

The STRACK NORMA standard parts are standardized components which are produced in accordance with its in-house standard or in conformity with international standardization. STRACK standard parts are produced with extremely high precision, ensure that designers and users have a helpful basis even at the calculation and offer phase when determining prices and deadlines for the mould to be produced.

The use of standard parts leaves the mould maker only with the work of providing the shaping contours, inserts, slides and temperature-control channels. Depending on the configuration of the moulds, this will result in production time that is 25 – 45% shorter than in the case of moulds made without the use of standard parts.

You are using an outdated web browser.

Errors may occur when using the website.